Glass lens polishing process

- 发布时间:2022-05-13

- 访问量:1623

- 访问量:1623

- 发布时间:2022-05-13

- 访问量:0

When polishing with polishing machine and polishing powder or polishing liquid, parameters such as polishing time and pressure should be set. After polishing, it should be cleaned and soaked immediately, otherwise the polishing powder will be solidified on the glass, leaving traces.

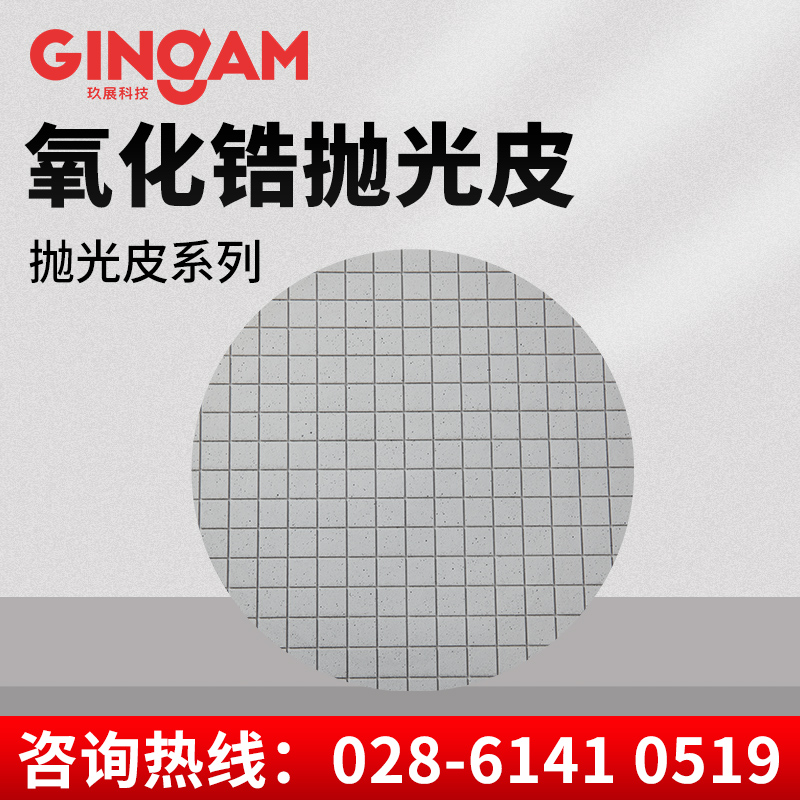

1. The material of the polishing powder The polishing powder is usually composed of cerium oxide, aluminum oxide, silicon oxide, iron oxide, zirconium oxide, chromium oxide and other components. Different materials have different hardness and different chemical properties in water, so the application occasions vary. Alumina and chromia have a Mohs hardness of 9, ceria and zirconia have a Mohs hardness of 7, and iron oxide is lower. Cerium oxide and silicate glass have high chemical activity and equivalent hardness, so they are widely used in glass polishing. In order to increase the polishing speed of cerium oxide, fluorine is usually added to the cerium oxide polishing powder to increase the grinding rate. Mixed rare earth polishing powder with low cerium content is usually doped with 3-8 fluorine; pure cerium oxide polishing powder is usually not doped with fluorine. For ZF or F series glass, because of its low hardness and high fluorine content, it is better to use fluorine-free polishing powder.

2. The particle size of cerium oxide The larger the particle size of cerium oxide, the greater the grinding force and the more suitable for harder materials. ZF glass should use finer polishing powder. It should be noted that the particle size of all cerium oxides has a distribution problem. The average particle size or median diameter D50 only determines the polishing speed, while the maximum particle size Dmax determines the polishing accuracy.

Optical cold working production operation 3 high and low. Therefore, to obtain high precision requirements, the maximum particle size of the polishing powder must be controlled.

3. Hardness of polishing powder The real hardness of polishing powder is related to the material. For example, the hardness of cerium oxide is about 7 on the Mohs scale, and all kinds of cerium oxide are similar. But different cerium oxide bodies feel different hardness, because cerium oxide polishing powder is usually agglomerate. Of course, some polishing powders are added with harder materials such as alumina, which will increase the grinding rate and wear resistance.

4. Concentration of polishing slurry The concentration of slurry during polishing determines the polishing speed. The higher the concentration, the higher the polishing speed. When using small particle polishing powder, the slurry concentration should be adjusted appropriately

Lens polishing

After the optical lens is finely ground by the abrasive liquid, there is still a crack layer about 2-3 m thick on the surface. The method to eliminate this crack layer is polishing. The mechanism of polishing is the same as that of grinding, except that the material of the tool used is different from the polishing liquid. The materials used for polishing include cloth, polyurethane and pitch. Polished surface, the most commonly used material is high-grade polished asphalt. Using asphalt for polishing is to use the fine surface of the asphalt to drive the polishing liquid to grind the surface of the lens to generate heat, so that the glass melts and flows, melts the rough vertices and fills the valley bottom of the crack, and gradually removes the crack layer. At present, the polishing powder used for polishing glass lenses is mainly cerium oxide (CeO2), and the proportion of polishing liquid is different depending on the polishing period of the lens. Generally, a polishing liquid with a higher concentration is used in the initial stage of polishing and when clamping with the polishing mold. , After the surface of the lens is bright, use a polishing solution with a thinner concentration to avoid orange peel on the mirror surface (fogging on the surface of the lens). Polishing and grinding use the same motion mechanism. In addition to the different polishing tools and working fluids, the environmental conditions required for polishing are also more severe than those for grinding. The matters to be paid attention to in general polishing are as follows: the surface of the polishing asphalt and the polishing liquid must not contain impurities, otherwise the mirror surface will be scratched.

Chengdu Gingam Technology Co., Ltd.

地址 : No. 1 attached to building 8, No. 1111, Changshengqiao Road, north area of modern industrial port, Pidu District, Chengdu, Sichuan

电话 : 028-61410519

邮箱 : pd@pardang.com

扫一扫 更精彩

Copyright 2025 Chengdu Gingam Technology Co., Ltd. all rights reserved. All Rights Reserved 网站建设:聚诚在线

英文

英文

028-61410519

028-61410519 在线留言

在线留言